- HOME

- WrapUp for iPhone12Mini (Coyote)

Product Points

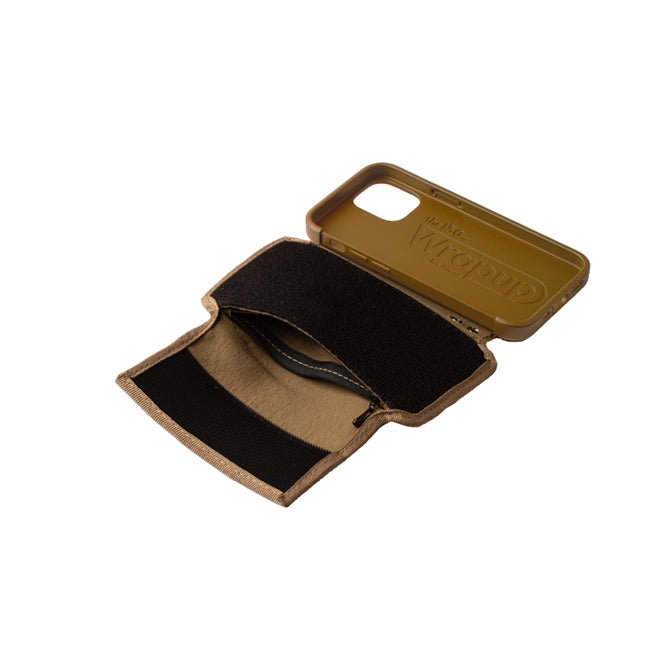

1 stretch material

Selected for expansion, restoration, texture, high quality, everything. If it grows too much, it will not be restored, it will be restored, but there is not enough growth, the texture is different, and many prototypes have been repeated. The double structure of this material (nylon 88/polyurethane 12) is the ideal realization. The water -repellent Eji Care 4WAY stretch nylon, which is not only left and right but also the top and bottom, is used to support waterproof life.

2 Cases compliant with mil standards

WrapUp contains important things, including iPhone, so we pursue toughness, assuming various scenes such as business and outdoors. In this realization, it is a direction to increase the size contrary to the slimness of the appearance, but it has a double -layer structure that combines a polycarbonate case and an inner case of TPU material. The polycarbonate case was applied to the overall harmony.

* Fall tests have been conducted under the standards compliant with Mil-STD-810H METHOD 516.8 US military standards

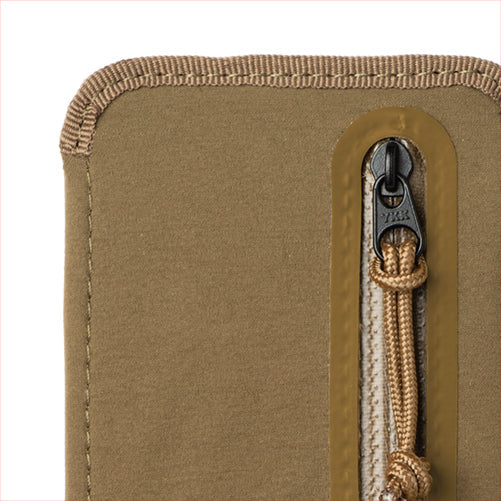

3 YKK AQUAGUARD

The zipper uses highly reliable YKK products. The luxurious matte texture enhances the design, laminates the surface of the zipper tape with a polyurethane film, and is treated to provide water stoppage.

4 YKK minifa

“Minifa” (“Minifa”) is the smallest YKK zipper, the thinnest and thin zipper, and succeeded in reducing the thickness of the product for the WrapUp pocket. The feeling of use is light and comfortable is one of the adoption.

5 -sided zipper (case back)

Select a material that is easier to hook on the back of the case. Finished with a durable military taste.

6 -sided zipper (inside the flap)

The inside of the flap was applied to the whole surface. Considering the thickness of the product, the type of hair is short. The internal surface zipper is designed to prevent the stored object from falling.

7 side buttons

The TPU material of the inner case functions as a side button with a shock absorption effect, as well as a soft and soft side button.

8 strap holes

By adopting a double hole, we have improved durability more strongly. A reinforcement board is implemented inside.

9 Strap (left)/Carabiner (right)

The MIL standard WrapUP is a specification that can withstand hard falling tests, but by implementing a strap on the main unit, it prevents falling. By using a carabiner together, it can also prevent falling when WrapUp is fixed to the back strap.

10 piping

The flap side (cut surface) has a lot of contact and is easily damaged, so piping is applied to achieve tough and military outfit.

11 Tactical code

A tactical code is attached to the slider of the front water stop zipper so that it can be accessed more comfortably. Milspec quality U.S. ATWOOD ROPE code is adopted to improve functionality and design.